Modular Air Cargo Pallet

Modular Air Cargo Pallet

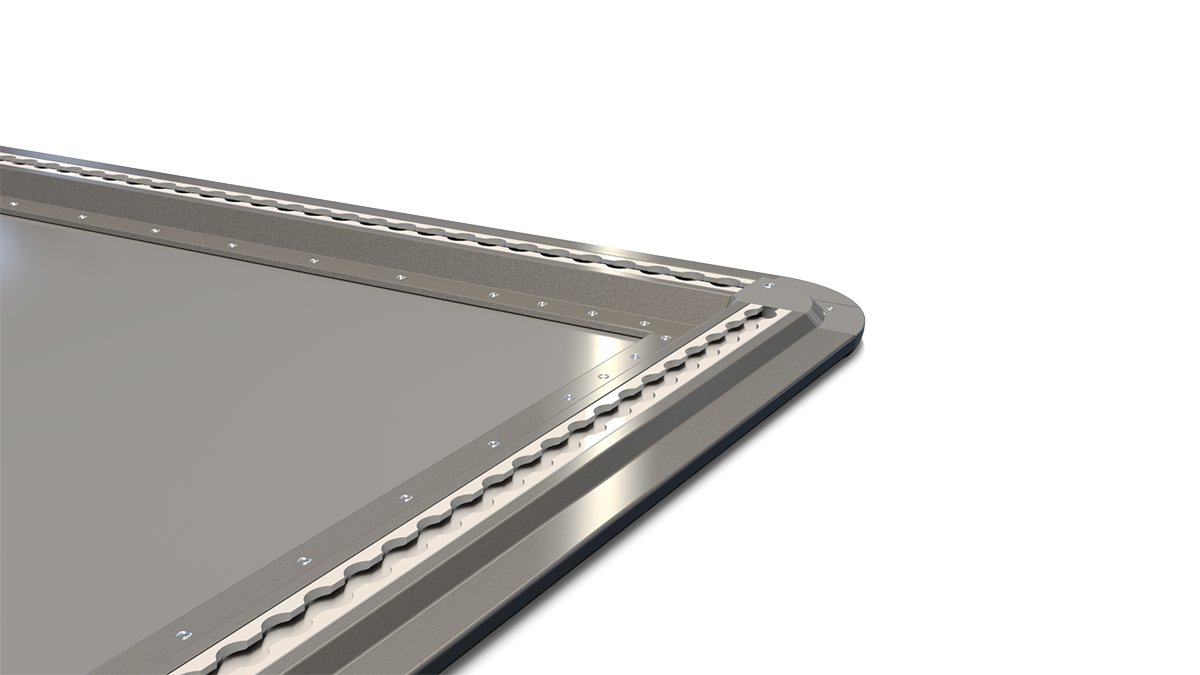

FLY IN TECH’s Modular Air Cargo Pallets are Type 2 ULD and is certified by the MOLIT and FAA (TSO-C90) with reference to AS36100; with a special feature that allows the seat track and corner to be detachable.

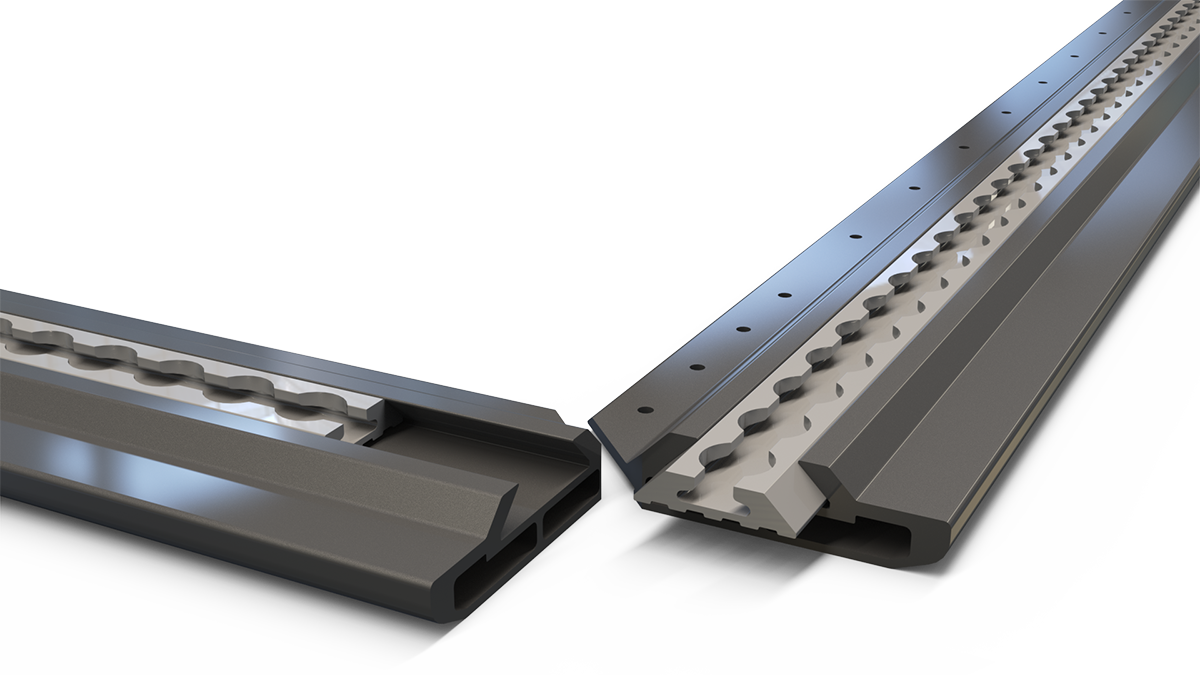

- Special Feature, Replace Seat Tracks and Corner parts by removing only 2 rivets.

- For the damaged track, The entire base extrusion profile is not needed to replace the damaged track as it used to be, from now on only damaged track rail can be replaced and use the base extrusion as is.

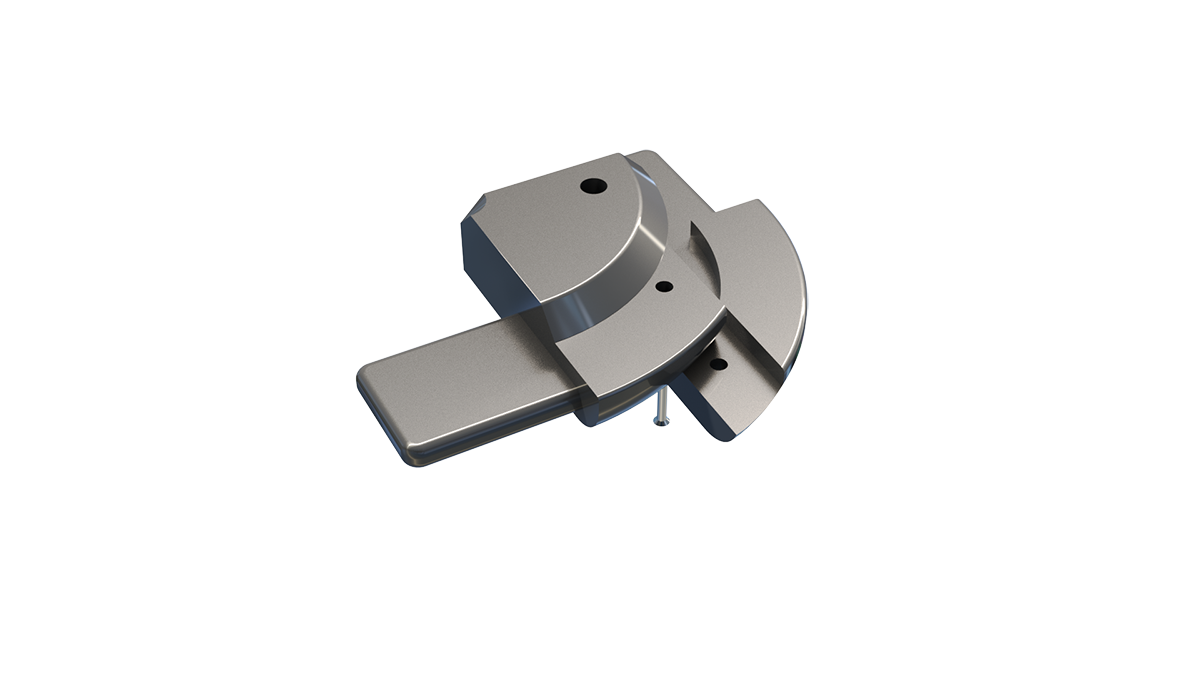

- Easy Replacement of Corner Parts Never Before, Simply remove and replace two rivets by yourself, do not need to remove all rivets from the base profiles and sheet, it only takes 5 minutes to replace corner.

- Solid Durability, The conditions and test required for TSO approval of this article are minimum performance standards. The Ultimate load testing was performed to verify that ULD meets the design criteria specified for strength and deformation in accordance with 14 CFR Part 25.305, and FT011 made of high strength 7000 aluminum alloy was satisfactorily performed.

- Modular functionality is applicable to all types of air cargo pallets.

About ULD maintenance cost

Find Your Annual Repair Cost for Air Cargo Pallet =

Total Number of Pallet you have X Annual Number of Repairs per Unit X Repair cost you paying for an unit

ULD Repair Cost Comparison Table

| Item | ⓐ | ⓑ | ⓒ | Annual Repair Cost for Pallet | Purchase New Pallet | |

|---|---|---|---|---|---|---|

| Your Pallet in use | Stock (Qty) | Annual Number of Repairs per unit |

Repair Cost per Unit (USD $) (Cost may vary depending on repair station) |

ⓐ x ⓑ x ⓒ | Giving up on repairs and buying a new one, that's another extra cost. |

|

| 5,000 units | Assuming 2 repairs per year | Inspection Fee | 50 | |||

| 10,000 units | Transportation Fee | 50 | ||||

| 20,000 units | Labor Cost / person | 45 to 85 | ||||

| 30,000 units | Number of Worker | 2 ~3 Workers | ||||

| 50,000 units | Parts Cost | Vary (Corner and or Base Edge) |

||||

| 100,000 units | Hour (Corner) | Over 2hrs | ||||

| 200,000 units | Hour (Track Rail) | Over 3hrs | ||||

| Find the cost of repairs and replacements | $355 Min. + Part cost w/3hrs | Operating expenses | ||||

| Modular Air Cargo Pallet | Qty. | Assuming 2 repairs per year | $145 Min. + Part cost w/less 1hr | ⓐ x ⓑ x ⓒ | ||

| "The lips of the track are a mess, really want to throw away the entire Extrusion Base because of repair costs? The Modular Air Cargo Pallet has separate seat track and extrusion base. Only necessary parts can be replaced, and Continue to use the Extrusion Base as is and save 1/2 the cost. And can you guess how much you could save in annual repair costs if you replaced all your pallets with Modular Air Cargo Pallet?" |

||||||

| ✓ Also looking at the parts cost, the seat track and prefabricated corners of the modular air cargo pallets are much more economical and easier to replace than the one-piece extruded profiles you've been using. | ||||||